LEVIATHAN MINE, CA

6 Miles East of Markleeville, CA

Latitude: 38.706295

Longitude: -119.652117

I was unable to photograph the mine itself due to a forest fire. Mountain roads leading to the mine were closed. The ground smoked with fire as we stopped roughly 1 mile from the mine entrance. Fire crews worked hard across the area smothering a wildfire that had been burning for roughly a week.

Images are from the surrounding area and the mine is just beyond the tree line in several of the photographs.

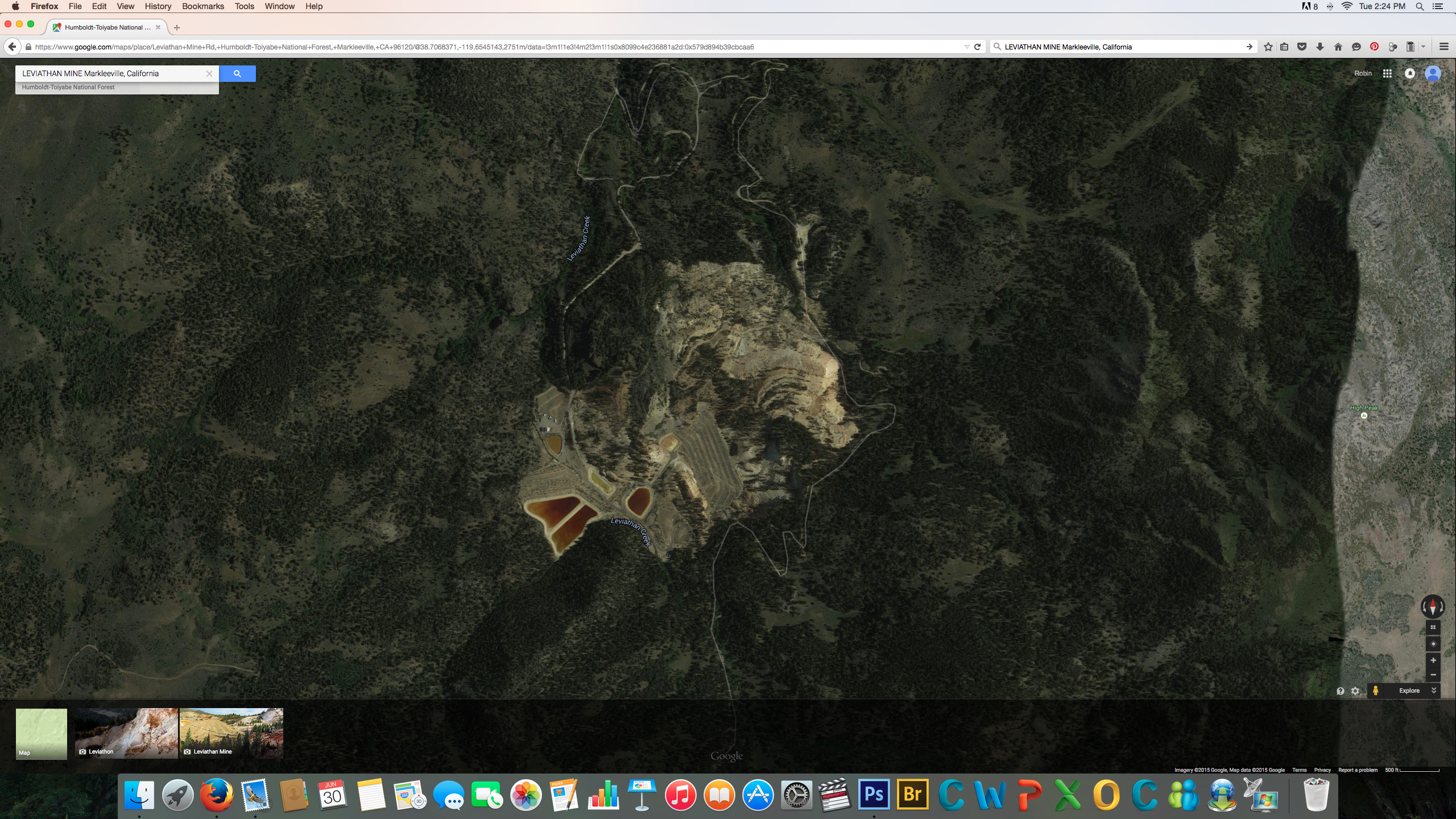

Leviathan Mine is an abandoned open-pit sulfur mine high on the eastern slope of the Sierra Nevada, in Alpine County CA. The mine, 24 miles southeast of Lake Tahoe, has been contaminating a nine-mile stretch of mountain creeks. The Toiyabe National Forest surrounds the site, and there are no permanent residents within several miles. The stream system drains into Nevada about five miles from the mine and enters the picturesque Carson Valley nine miles downstream from the mine. Although there had been some mining activities for copper minerals since the 1860s, major environmental problems originated during the open-pit sulfur mining that occurred from 1951 through 1962. During this period, Anaconda used Leviathan Mine as a source of sulfur to dissolve copper from relatively low-grade ore at a mine near Yerington, NV. In 1962 Anaconda ceased operations and sold the property to a local interest. No significant mining activities have taken place since.

The high sulfur content in the waste rocks and fractures at the 250-acre mine site turns snowmelt, rain and groundwater into sulfuric acid, which leaches contaminants from the native minerals such as arsenic, copper, nickel, zinc, chromium along with aluminum and iron. This acid mine drainage then flows into the creek system at a number of points, devastating aquatic life until the creeks join the East Fork of the Carson River, a much larger flow. Since 1983, the State of California has invested millions of dollars to contour the pit and surrounding waste piles, channel Leviathan Creek around the major disturbed area and capture the most concentrated flow in a series of ponds. Except for high flow periods during the spring snowmelt, the acid rock drainage that has been identified produced roughly half of all the flow in Leviathan Creek. Until recent treatment activities, a thick layer of orange precipitate coated the streambed most of the year until it washed into the East Fork with the high spring runoff each year.

The investigation into impacts from the acid rock drainage will include contaminated sediment and soil along the stream system. The possibility exists that contaminants may be present in greater concentrations in these soils due to discharges from the mine and could pose an increased risk to plants and animals, and even to humans who might use these resources.

By 1997, the Washoe Tribe of Nevada and California asked EPA to get involved to fully address the contamination from the mine. Local governments in California and Nevada also voiced their support for intervention. After a number of voluntary measures in 1997 and 1998 proved inadequate, the Leviathan Mine was listed on the NPL in May 2000.

In 1999 and 2000, the State of California and the University of California-Davis developed an innovative two-phase lime treatment system to treat millions of gallons of the worst acid discharge that collects throughout the year in several large ponds on the mine site. The treatment occurs during the summer months to maximize the pond storage capacity and prevent overflow of the ponds in the winter and spring. The California Regional Water Quality Control Board – Lahontan Region – continues to capture the highly acidic waste from the Adit Seep and Pit Underdrain in the existing pond system and then treat the entire year’s accumulation during an intensive one- to two-month period during the summer. Pond overflow, initially considered the most serious contaminant source, has been prevented since 1999. In the wet year of 2006, nearly 20 million gallons were treated during the spring and summer. In very dry years such as 2007 and 2009, only three million gallons or less must be treated to completely empty the ponds. Improvements in equipment, process efficiency and monitoring are constantly being implemented (see end-of-year reports and other information at: http://www.waterboards.ca.gov/lahontan/water_issues/projects/leviathan_project/index.shtml

Atlantic Richfield Company, the successor to Anaconda, is capturing and neutralizing most of the remaining acid rock drainage as we develop long-term cleanup plans. A full-scale biological treatment system designed by the University of Nevada-Reno and constructed and operated by Atlantic Richfield has gained international attention for its remarkable success in treating one of the seeps year-round. Since 2003, the biological treatment system captured and treated all the acidic drainage captured at the Aspen Seep, typically more than three million gallons per year.

Atlantic Richfield has used various lime treatment systems to treat approximately six million gallons of acid mine drainage annually from the Delta Seep and Channel Underdrain, but only during the summer months.

Another stage of early response actions for the Channel Underdrain, Delta Seep and Aspen Seep is now in operation (see the most recent annual reports and the 2008 and 2009 Removal Action Memo and Settlement Documents in the Documents and Reports section below). Atlantic Richfield Company attempted to design a system to treat all the known discharge sources for the entire year to reduce environmental damage, allow a more thorough evaluation of remaining risks to the downstream area and to assess the effectiveness and reliability of potential long-term treatment options. Difficulties were encountered during 2006 indicated that a lime treatment plant is not likely to be effective during the winter without very large investments in safe access and power at this remote mountain location. Improvements in the temporary lime treatment and biological systems, including a state-of-the-art High Density Sludge (HDS) lime treatment plant, were completed in 2009. The systems have improved efficiency with less waste generated and are also allowing an earlier commencement of the treatment season for the Channel Underdrain and Delta Seep (see Atlantic Richfield end-of-year reports). It is expected that the decision-making and design processes will continue for the next several years before a proposed plan for a long-term, year-round remedy is developed for public comment.